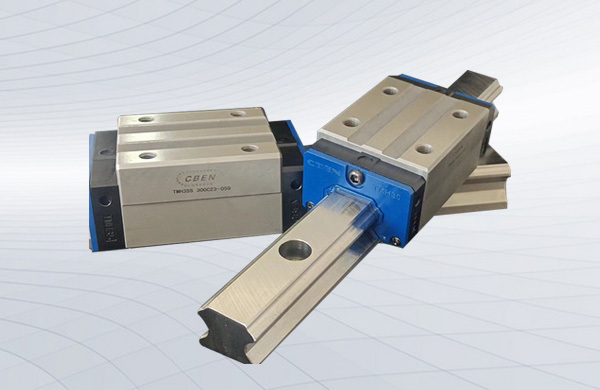

How to avoid the friction of linear guide

In most cases, fluid lubrication is limited to the boundary area, and direct friction caused by metal contact is unavoidable. In this friction, a large amount of energy is wasted as friction loss.

How to avoid the friction of linear guide

In most cases, only grease lubrication is sufficient, which makes it very easy to rotate the sliding block of the linear guide rail and the guide rail for micro-clearance or negative clearance in the planning and utilization and maintenance of the lubrication system of the machine tool, thus greatly improving the overall rigidity and activity accuracy of the guide rail. Can be used in extraordinary situations such as dust, harsh weather and water use.

The self-moistening module can not only increase the convenience of user maintenance, but also enable customers to directly install the self-moistening module kit on the slider to achieve the effect of lubricating parts. The machine plan receives the deviation of the placement surface due to the elastic deformation of the steel ball in the rotating linear guide rail, which can lower the flatness request of the fundamental surface of the guide rail placement and lower the machining cost. The linear guide rail has the characteristics of receiving after averaging the alignment deviations such as verticality, flatness and intersection that occur during the processing and assembly of the foundation of the placement guide rail. Therefore, the adoption of linear guides can greatly improve the effectiveness of the machine plan.

The friction loss of the rolling surface is also reduced accordingly, so that the linear rolling guide system can be in a high-precision state for a long time.

Key words:

Next article

Next article

Share