Linear guide how dust?

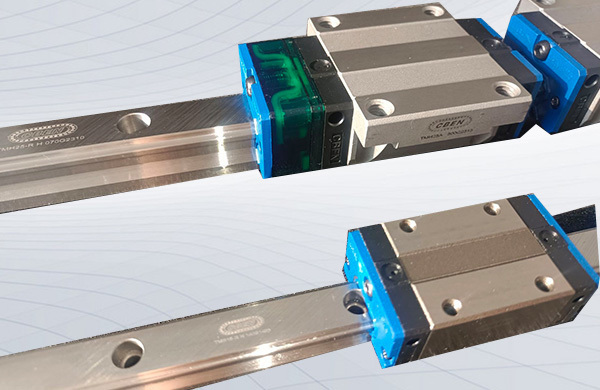

The linear guide is easy to inhale dust during the entire application process, and the inhaled dust will also be deposited on the surface of the linear guide and in the screws, so that the application cycle time of the flip linear guide is sharply reduced. If the dust is not properly, it will directly damage the linear motion system and shorten the application cycle time. So how should we do a good job of linear guide dust?

1. Use special sealing gasket for uniform linear motion system. As we all know, there are many gaps in the linear guide drive system, and it is easy to deposit ash and debris. If you want to ensure that all systems are sealed, try to seal these gaps with gaskets.

2. Use special telescopic dust cover for linear guide rail. The use of dust cover has a good expected effect on dust. The dust cover used in extreme office environments is very flexible. It can be scaled and used freely in harsh environments. Some specifications and models must use special soft telescopic dust covers and special dust covers.

Key words:

Share