What is the effect of linear guide on the performance of precision instruments?

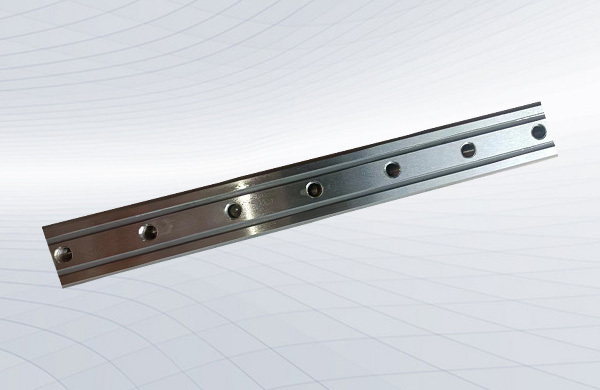

The linear guide is used as a device to support and guide the moving parts, and its main function is to make the mechanical parts move smoothly on the linear track. In precision instruments, the accurate positioning of the position and the stability of the movement are very important to the performance of the instrument. Through its high-precision manufacturing process and superior material properties, the linear guide can effectively improve the positioning accuracy and motion stability of the instrument, thereby improving the performance of the entire precision instrument.

Linear guide plays an important role in improving the load capacity of precision instruments. In the working process of precision instruments, they often need to bear a variety of complex forces and loads. For example, in medical equipment, precision instruments need to withstand various pressures generated during surgery to ensure that doctors can perform accurate and stable surgery. In the field of scientific research, precision instruments may need to withstand the enormous force of high-speed rotation.

The linear guide can effectively improve the load capacity of the instrument through its reasonable structure and high-quality materials. This increase in load capacity enables the precision instrument to maintain stable operation under various extreme working conditions and extends the service life of the instrument. This is of great significance to ensure the reliability and safety of medical equipment and improve the accuracy and sustainability of scientific research. The application of linear guide in precision instruments not only improves the load capacity, but also brings greater possibilities and stability to the development of related fields.

Linear guide also has an important influence on the service life of precision instruments. The use of high-quality linear guides can effectively reduce the wear and damage of parts, extend the service life of the entire instrument, reduce maintenance costs, and improve the reliability of the instrument. This is critical for many industries, especially in medical equipment and scientific research, where instruments are often expensive and need to be stable for long periods of time.

In practical applications, choosing the right linear guide is essential to improve the performance of precision instruments. Different precision instruments may face different working environments and working requirements, such as some require high-speed movement, some need to bear heavy loads, and some need to work in special environments. According to the specific needs to choose the appropriate linear guide type and specifications, combined with reasonable installation and maintenance, give full play to its role, improve the performance of precision instruments.

Key words:

Previous article

Next article

Previous article

Next article

Share